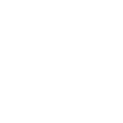

The preparation of a concrete substrate requires careful preliminary checks as specified in our Professional Training Courses. The following is the preparation cycle necessary for coating a cement screed in resin that does not present any humidity, such as when a floor laid on a slab.

ON CONCRETE SCREED LAYED ON SLAB

FASE 1 • Verification and preparation of the support

Before starting, make sure that there is no humidity. Carefully verify that the surface is properly prepared and is in the condition indicated in our Professional Training Courses.

FASE 2 • Primer application

R101 CEMENT PRIMER (A+B)

Roller application of transparent water-based epoxy primer for absorbent substrates.

Product: R101 CEMENT PRIMER (A+B)

Dilution: 100% Water

Tool: Medium hair nylon roller

Pot-life a 25°: 105 minutes

Overlay time at 25°: 4 hours

Indicative consumption: 0,10 Kg/m2

FASE 3 • Mortar primer application

R211 MALTA (A+B+C)

Water-based epoxy mortar casting application. Consumption varies according to the conditions of the existing substrate. After drying, sand

with abrasive discs with a grain of 36 to 120 (depending on the effect).

Product: R211 MALTA (A+B+C)

Dilution: Ready to use

Tool: Sawtooth trowel (mm 6×6)

Pot-life at 25°: 15 minutes

Overlay time at 25°: 24 hours

Indicative consumption: 1,50 Kg/m2

PRODUCTS USED

Breathable bi-component anchor formulated with water-based epoxy resins. Primer for all absorbent surfaces.

Mixture/weight ratio: A=600 B=400

Consumption: Variable

Pot-life: 105 min

Colour: –

Semi-self-leveling, tri-component, water-based epoxy mortar for base coatings on floors. Supplied in white color.

Mixture/weight ratio: A=220 B=113 C=667

Consumption: Variable

Pot-life: 15 min

Colour: –

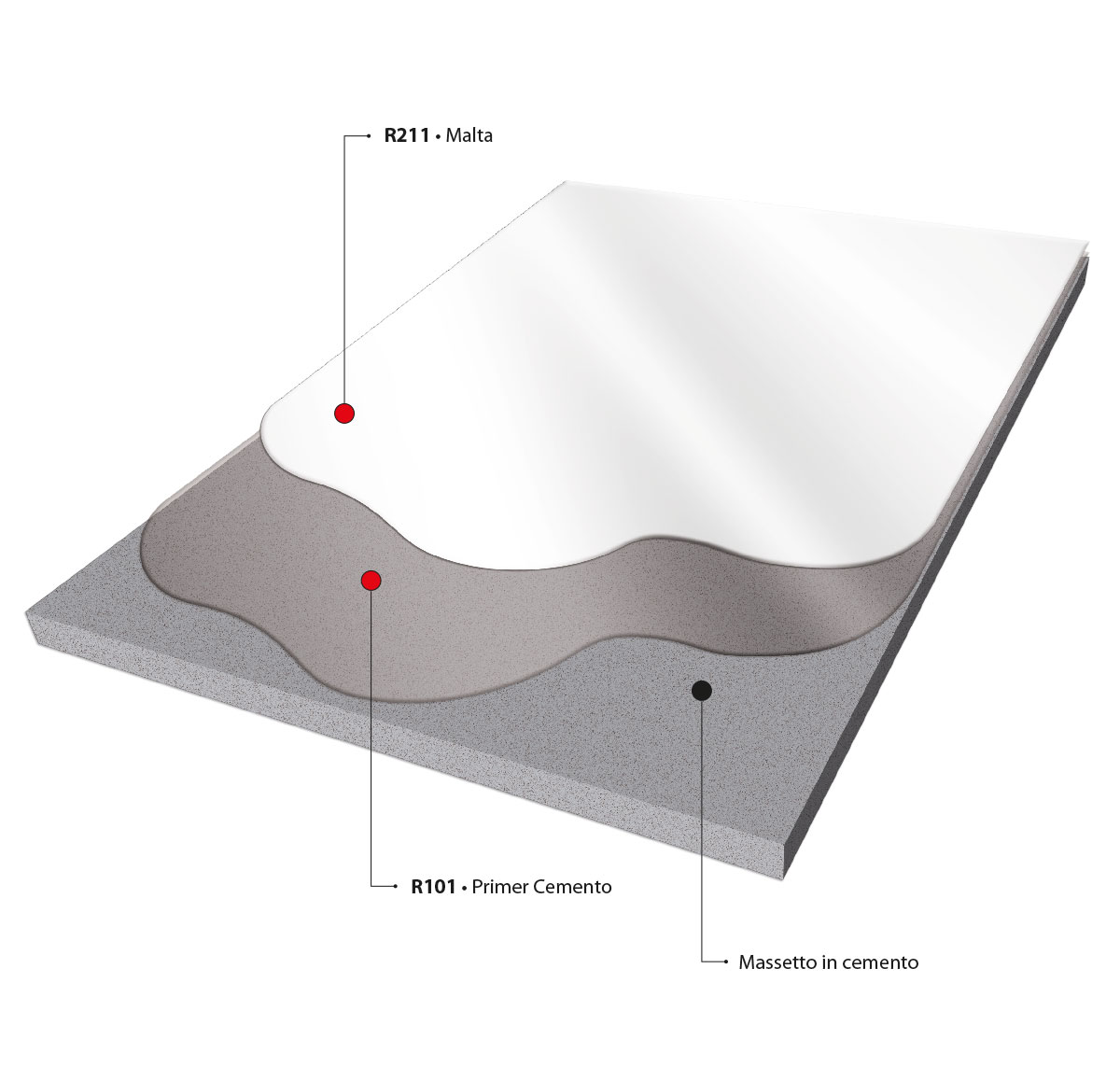

CONCRETE SCREED LAYED ON GROUND

The preparation of a concrete substrate requires careful preliminary checks as specified in our Professional Training Courses. The following is the preparation cycle necessary to coat a cementitious screed laid on an embankment in resin which may be damp.

FASE 1 • Verification and preparation of the support

Before the intervention, evaluate the level of humidity in the substrate. Carry out an accurate verification of the surface on which you are going to work and adequate preparation respecting what is specified in our Professional Training Courses.

FASE 2 • Primer application

R101 PRIMER CEMENTO (A+B)

Roller application of transparent water-based epoxy primer for absorbent substrates.

In this particular case, the next step can be applied with the “FRESCO SU FRESCO” system.

Product: R101 CEMENT PRIMER (A+B)

Diluizione: 300% Water

Tool: Medium brush nylon roller

Pot-life at 25°: 105 minutes

Overlay time at 25°: 0 hours

Indicative consumption: 0,05 Kg/m²

FASE 3 • Substrate preparation

R203 ERRE-BLOCK (A+B+C)

Application with trowel of a layer of connection to the cement surface with the function of a vapor barrier.

Apply in adequate quantity. Before proceeding with the next phase, always check the humidity level.

Prodotto: R203 ERRE-BLOCK (A+B-C)

Diluizione: Pronto uso

Attrezzo: Frattone americano acciaio

Pot-life a 25°: 90 minuti

Tempo sovrapplicazione a 25°: 24-36 ore

Consumo indicativo: 0,70 Kg/m²

FASE 4 • Substrate preparation

R203 ERRE-BLOCK (A+B+C)

Application with trowel of a second layer of connection to the surface with vapor barrier function.

Apply in adequate quantity. Before proceeding with the next phase, always check the humidity level.

Product: R203 ERRE-BLOCK (A+B-C)

Dilution: Ready to use

Tool: American steel trowel

Pot-life at 25°: 90 minutes

Overlap time at 25°: 24-36 hours

Indicative consumption: 0,70 Kg/m²

FASE 5 • Primer mortar application

R211 MALTA (A+B+C)

Water-based epoxy mortar casting application. Consumption varies according to the conditions of the existing substrate. Once dry, sand with 36 to 120 grit abrasive discs (depending on the effect).

Product: R211 MALTA (A+B+C)

Dilution: Ready to use

Tool: Sawtooth trowel (mm 6×6)

Pot-life at 25°: 15 minutes

Overlap time at 25°: 24 hours

Indicative consumption: 1,50 Kg/m²

PRODUCTS USED

Breathable bi-component anchor formulated with water-based epoxy resins. Primer for all absorbent surfaces.

Mixture/weight ratio: A=600 B=400

Consumption: Variable

Pot-life: 105 min

Colour: –

Tri-component formulation (A + B + C) based on liquid epoxy resins in aqueous emulsion and hydraulic binders, used as a base for wet surfaces. Particularly resistant to moisture in counter thrust.

Mixture/weight ratio: A=300 B=200 C=500

Consumption: 0,4-1,0 kg/m² (per coat)

Pot-life: 45 min

Colour: –

Semi-self-leveling, tri-component, water-based epoxy mortar for base coatings on floors. Available in white color.

Mixture/weight ratio: A=220 B=113 C=667

Consumption: Variabile

Pot-life: 15 min

Colour: –

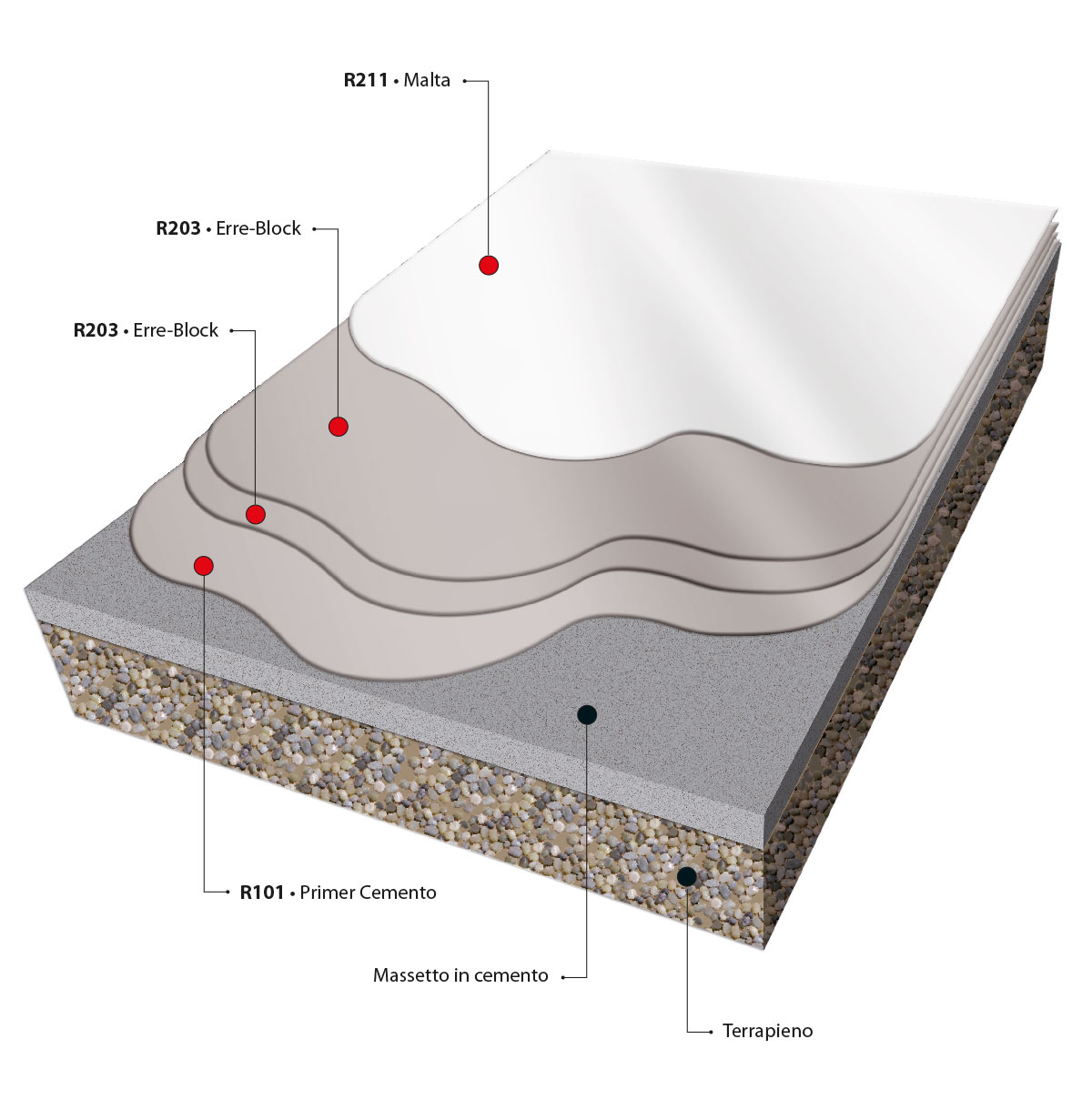

TILES LAYED ON SLAB

The preparation of a tiled floor requires, depending on the different type (narrow, medium or wide grout), careful preliminary checks as specified in our Professional Training Courses. The following is the preparation cycle necessary to coat a tiled surface in resin that does not show any rising damp, as in the case of a tile floor laid on a slab.

FASE 1 • Verification and preparation of the support

Before the intervention, evaluate that there is no rising damp. Carefully verify the surface on which you are going to work and adequate mechanical treatment respecting the specifications

in our Professional Training Courses.

FASE 2 • Substrate preparation

R202 FIBRE BASE (A+B+C)

Coated application of a reinforced base layer for the regularization of the surface of the tiles and

joint saturation.

Product: R202 FIBER BASE (A+B+C)

Dilution: Ready to use

Tool: American steel trowel

Pot-life at 25°: 30 minutes

Overlay time at 25°: 24 hours

Indicative consumption: 1 Kg/m²

FASE 3 • Primer application

R101 CEMENT PRIMER (A+B)

Roller application of transparent water-based epoxy primer for absorbent substrates.

Product: R101CEMENT PRIMER (A+B)

Dilution: 100% Water

Tool: Medium brush nylon roller

Pot-life at 25°: 105 minutes

Overlap time at 25°: 4 hours

Indicative consumption: 0,10 Kg/m²

FASE 4 • Mortar primer application

R211 MALTA (A+B+C)

Water-based epoxy mortar casting application. Consumption varies according to the conditions of the existing substrate. After drying, sand

with 36 to 120 grain abrasive discs (depending on the desired effect).

Product: R211 MALTA (A+B+C)

Dilution: Ready to use

Tool: Sawtooth trowel (mm 6×6)

Pot-life at 25°: 15 minutes

Overlap tie at 25°: 24 hours

Indicative consumption: 1,50 Kg/m2

PRODUCTS USED

Breathable bi-component anchor formulated with water-based epoxy resins. Primer for all absorbent surfaces.

Mixture/weight ratio: A=600 B=400

Consumption: Variable

Pot-life: 105 min

Colour: –

Semi-self-leveling, tri-component, water-based epoxy mortar for base coatings on floors. Availalble in white.

Mixture/weight ratio: A=390 B=110 C=500

Consumption: 1 kg/m²

Pot-life: 30 min

Colour: –

Semi-self-leveling, tri-component, water-based epoxy mortar for base coatings on floors. Supplied in white color.

Mixture/weight: A=220 B=113 C=667

Consumption: Variable

Pot-life: 15 min

Colour: –

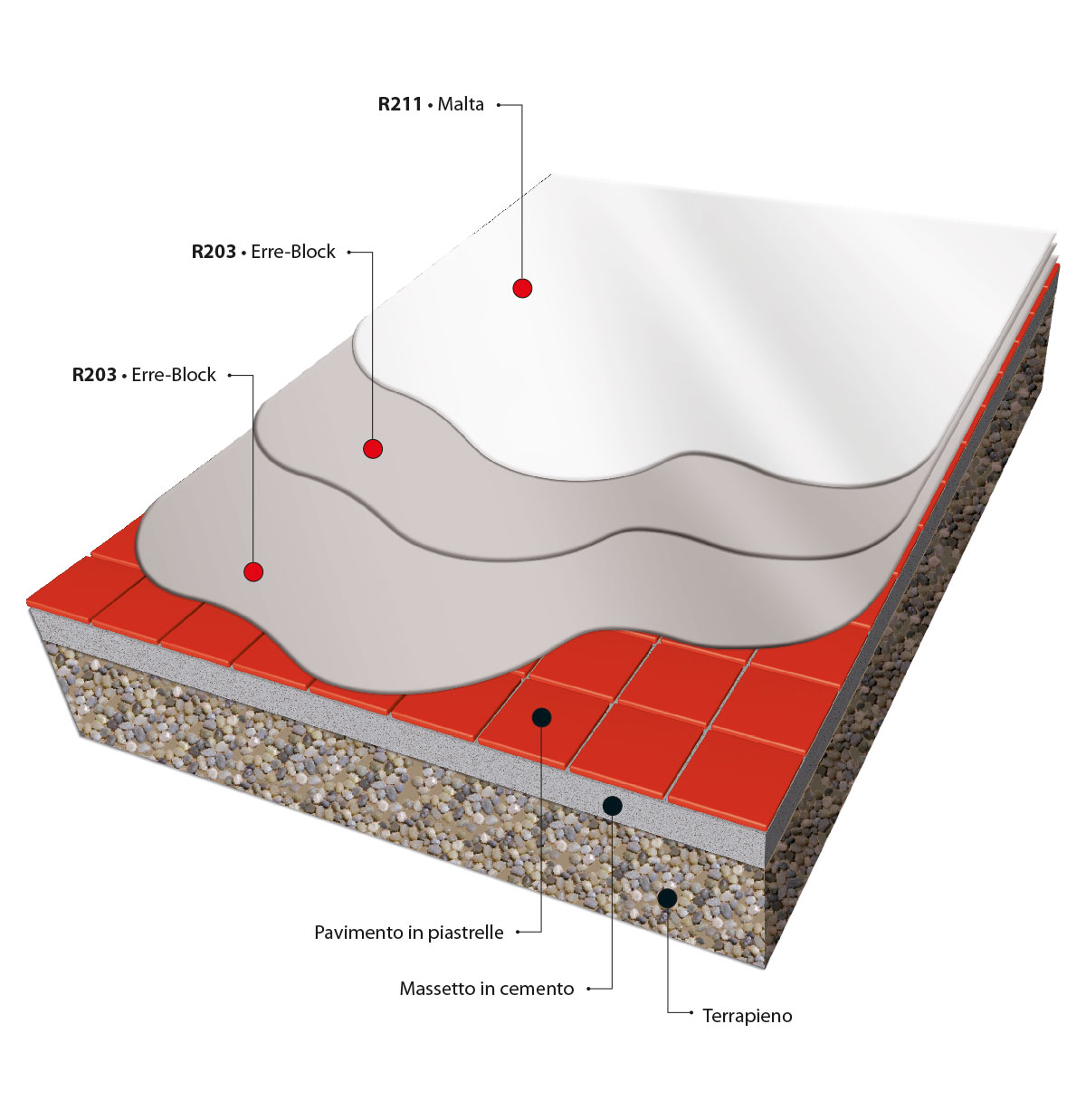

TILES PLACED ON THE GROUND

The preparation of a tiled floor requires, according to the type (narrow, medium or wide grout), careful preliminary checks as specified in our Professional Training Courses. The following is the preparation cycle necessary to coat a tiled surface laid on an embankment in resin which may have a rising damp.

FASE 1 • Verification and preparation of the support

Before starting, evaluate the level of humidity in the substrate. Carefully verify the surface on which you are going to work and that the mechanical treatment adequately respects what is specified in the

our Professional Training Courses.

FASE 1 • Substrate preparation

R203 ERRE-BLOCK (A+B+C)

Application with a trowel with one layer of connection to the cement surface with the function of a vapor barrier.

Apply in adequate quantity. Before proceeding with the next phase, always check the humidity level.

Product: R203 ERRE-BLOCK (A+B-C)

Dilution: Ready to use

Tool: American steel trowel

Pot-life at 25°: 90 minutes

Overlay time at 25°: 24-36 hours

Indicative consumption: 1,20 Kg/m²

FASE 2 • Substrate preparation

R203 ERRE-BLOCK (A+B+C)

Application with a trowel with a second layer of connection to the surface with vapor barrier function.

Apply in adequate quantity. Before proceeding with the next phase, always check the humidity level.

Product: R203 ERRE-BLOCK (A+B-C)

Dilution: Ready to use

Tool: American steel trowel

Pot-life at 25°: 90 minutes

Overlay time at 25°: 24-36 hours

Indicative consumption: 0,70 Kg/m²

FASE 3 • Mortar primer application

R211 MALTA (A+B+C)

Water-based epoxy mortar casting application. Consumption varies according to the conditions of the existing substrate. Once dry, sand with 36 to 120 grit abrasive discs (depending on the desired effect).

Prodotto: R211 MALTA (A+B+C)

Dilution: Ready to use

Tool: Sawtooth trowel (mm 6×6)

Pot-life at 25°: 15 minutes

Overlay time at 25°: 24 hours

Indicative consumption: 2,50 Kg/m²

PRODUCTS USED

Tri-component formula (A + B + C) based on liquid epoxy resins in aqueous emulsion and hydraulic binders, used as a base for wet surfaces. Particularly resistant to moisture in counter thrust.

Mixture/weight ratio: A=300 B=200 C=500

Consumption: 0,4-1,0 kg/m² (per hand)

Pot-life: 45 min

Colour: –

Semi-self-leveling, tri-component, water-based epoxy mortar for base coatings on floors. Available in white.

Mixture/weight ratio: A=220 B=113 C=667

Consumption: Variable

Pot-life: 15 min

Colour: –